If we want create industrial automation control system with PLC or Microcontroller, first we have to do is identify the components that will be involved industrial automation. We can make industrial automotion component categories by their function in our documentation so we can understand what is actually happening as each component changes state.

Industrial automation control component its very wide knowledge sector. Its can not be discussed in here for all, but I try to make a concept step to learn the component most usage for industrial automation systems such as contactor, timers, solenoids, PLC, Microcontroler, etc.

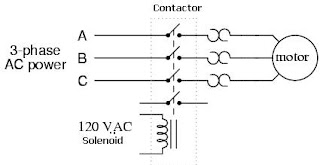

Contactors / Relays

Motors and other power consuming devices are usually controlled by contactors having heavy-duty contacts that can switch the power circuits safely. The contactor will be actuated by an electromagnetic solenoid (coil) which pulls the contacts closed when energized. They will also have an arc-suppressing cover to quench the arc formed when the contacts open under load.

Motors and other power consuming devices are usually controlled by contactors having heavy-duty contacts that can switch the power circuits safely. The contactor will be actuated by an electromagnetic solenoid (coil) which pulls the contacts closed when energized. They will also have an arc-suppressing cover to quench the arc formed when the contacts open under load. See Figure down here.

So contactor is the most important Industrial automation component